Cleanroom Products for Controlled and Compliant Environments

Autoclave A4 Cleanroom Paper

Autoclave A4 Cleanroom Paper is engineered for controlled cleanroom environments where preventing particle contamination and chemical migration is critical. It is autoclavable, low-lint, and designed to maintain print clarity and durability during sterilization and routine cleanroom documentation.

Features:

• Autoclavable and heat-resistant

• Special protective coating minimizes release of particles, fibres, and micro-organisms

• Compliant with RoHS guidelines

• Weight: 80 GSM

• Available Colours: White, Blue

• Dimensions: A4 (297 × 210 mm)

• Retains ink and toner to reduce smudging

• Suitable for laser printers and photocopiers

• Designed for ISO Class 5–7 cleanroom environments

Sterile Cleanroom Marker

Gamma Irradiated Marker is designed for sterile and controlled cleanroom environments, providing safe and reliable marking on cleanroom paper, bags, labels, and critical documentation. Each marker is gamma sterilized to minimize bioburden and particle contamination, ensuring suitability for pharmaceutical, biotech, and medical device operations.

Features:

• Gamma sterilized for cleanroom and sterile areas

• Available Ink Colours: Black & Blue

• Low-particle, low-odor, quick-drying ink

• Smudge-resistant and durable on cleanroom substrates

• Compatible with cleanroom paper, bags, labels, and instruments

• Ideal for sterile production, QA/QC, and documentation zones

• Suitable for ISO-classified cleanroom environments

Sterile Cleanroom Pen

Gamma Irradiated Pen is designed for sterile and controlled cleanroom environments, ensuring safe and reliable writing for batch records, labels, and critical documentation. Each pen is gamma sterilized to reduce bioburden and particle contamination, making it suitable for pharmaceutical, biotech, and medical device applications.

Features:

• Gamma sterilized for cleanroom and sterile processing areas

• Ink Colours Available: Black & Blue

• Low-particle, low-odor, quick-drying ink

• Smudge-resistant — ideal for records and documentation

• Compatible with cleanroom paper, labels, and logbooks

• Designed for ISO-classified cleanrooms

• Suitable for QA/QC, production, and sterile gowning areas

Cleanroom Autoclavable Safety Goggles

Cleanroom Autoclavable Safety Goggles are designed for sterile and controlled environments where eye protection and contamination control are essential. Made from durable, heat-resistant materials, these reusable goggles withstand repeated autoclave sterilization cycles while maintaining clarity and shape. The clear polycarbonate lens offers wide visibility, and the ergonomic frame ensures comfort during extended use — suitable for pharmaceutical, biotech, microbiology, and medical device applications.

Features:

• Autoclavable — supports multiple steam-sterilization cycles

• Clear polycarbonate lens with wide, unobstructed view

• Anti-fog and anti-scratch coating for visual clarity

• Indirect-vent design to reduce particle entry

• Soft, ergonomic frame with adjustable latex-free strap

• Compatible for use over prescription glasses (OTG)

• Cleanroom-compatible, suitable for ISO & GMP areas

Cleanroom Tape

Autoclave Indicator Tape is used for sealing sterilization packs, trays, and wrapped instruments while visually confirming exposure to steam sterilization. The tape features a chemical indicator that changes colour after autoclaving, helping operators verify that the load has undergone the sterilization cycle. Designed for cleanroom, pharmaceutical, microbiology, and medical device environments, it provides strong adhesion, clean removal, and reliable performance on paper, fabric, and non-woven wraps.

Features:

• Steam-sensitive indicator ink for visual sterilization confirmation

• Colour change after autoclave exposure (typically 121–134°C)

• Strong adhesive — secure bonding to wraps and pouches

• Leaves minimal residue after removal

• High tack and tear-resistant backing

• Suitable for packs, trays, and instrument wrapping

• Ideal for hospitals, pharma production, QC labs, and sterile processing areas

Autoclave Indicator Tape

Autoclave Indicator Tape by Lifecell Technologies is a high-quality chemical indicator tape designed to visually verify exposure to steam sterilization processes. The tape features precision-formulated indicator stripes that undergo a clear and irreversible color change when subjected to standard autoclave conditions, enabling quick identification of sterilized packs.

Engineered for use in pharmaceutical manufacturing, biotechnology laboratories, hospitals, and cleanroom environments, Lifecell autoclave indicator tape adheres firmly to sterilization wraps, pouches, and trays. It maintains integrity during high temperature and moisture exposure and removes cleanly without leaving adhesive residue.

Supporting GMP and quality assurance requirements, Lifecell Technologies’ autoclave indicator tape provides a simple yet reliable solution for sterilization monitoring, load differentiation, and process control, strengthening overall sterility assurance practices.

Sterilization Green Crepe Wrapping Paper

Sterilization Green Crepe Wrapping Paper is designed for wrapping medical instruments, trays, and packs before steam sterilization. Made from strong, medical-grade crepe material, it offers reliable barrier protection, durability, and drapeability to support safe sterilization and aseptic handling — ideal for hospitals, pharma facilities, sterile processing units, and cleanroom environments.

Features:

• Medical-grade, tear-resistant crepe wrapping paper

• Compatible with steam sterilization autoclave cycles

• Strong sealing strength with good barrier protection

• Controlled breathability for effective sterilization

• Excellent drapeability for trays and instrument packs

• Supports aseptic storage and sterile presentation

• Available sizes: 50×50 cm & 100×100 cm

• Suitable for CSSD, OT, pharma & sterile processing areas

Quilted Two-Ply Polyester Dry Wipes - Sterile/Non-Sterile

Quilted Two-Ply Polyester Dry Wipes are designed for critical cleaning and surface wiping in cleanrooms and controlled environments. Made from 2-ply polyester with a quilted structure, these wipes provide high absorbency, low particle generation, and excellent strength for wiping sensitive equipment, stainless steel surfaces, workbenches, and instruments. They are suitable for pharmaceutical, biotech, microbiology, and medical device applications.

Features:

• Two-ply quilted polyester construction for superior absorbency

• Low-lint, low-particle design for cleanroom compatibility

• High tensile strength — resists tearing during wiping

• Soft, non-abrasive material for sensitive surfaces

• Available sizes: 9×9 and 12×12

• Available in sterile and non sterile options

• Suitable for spill control, equipment cleaning, and surface wiping

• Ideal for ISO-classified cleanrooms, QA/QC, production & aseptic areas

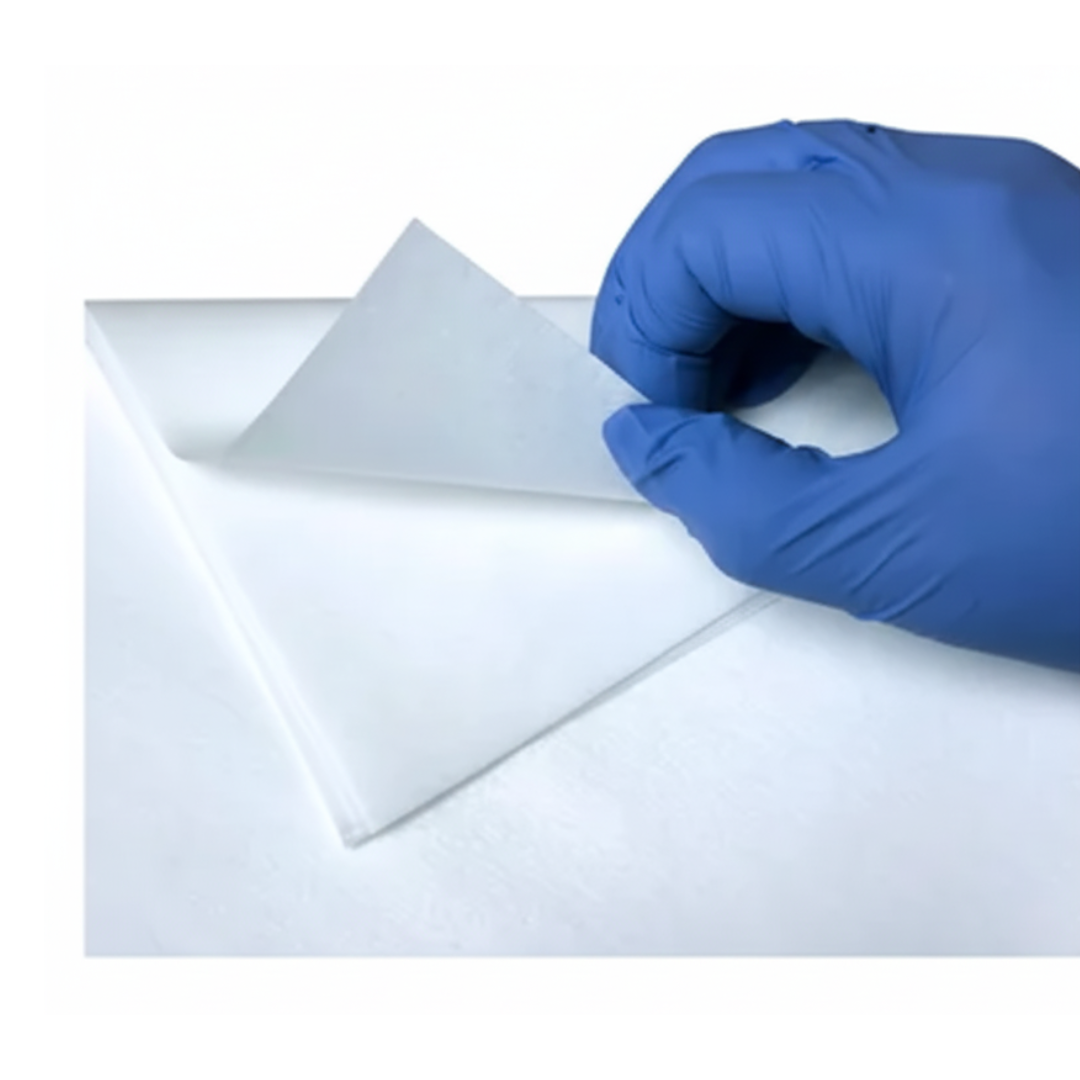

Single Ply Polyester Dry Wipes - Sterile/Non-Sterile

Single Ply Polyester Dry Wipes are designed for general cleaning, wiping, and contamination control in cleanrooms and controlled environments. Made from single-ply knitted polyester, these wipes offer low particle generation, smooth edges, and good absorbency for wiping equipment surfaces, instruments, workstations, and cleanroom benches. They are suitable for pharmaceutical, biotech, microbiology, and medical device applications.

Features:

• Single-ply knitted polyester construction for cleanroom applications

• Low-lint, low-particle design to minimize contamination

• Soft, non-abrasive surface — safe for sensitive components

• Good absorbency for routine wiping and spill control

• Laser-sealed or ultrasonically sealed edges to reduce fiber release

• Available sizes: 9×9 and 12×12

• Available in sterile and non-sterile options

• Suitable for equipment cleaning, surface wiping & production areas

• Ideal for ISO-classified cleanrooms, QA/QC & sterile processing zones

Non-Woven Poly Cellulose Dry Wipes - Sterile/Non-Sterile

Non-Woven Poly Cellulose Dry Wipes are designed for general cleaning, spill control, and surface wiping in cleanrooms and controlled environments. Made from a non-woven blend of polyester and cellulose, these wipes provide high absorbency, low particle generation, and good strength for wiping equipment, stainless-steel surfaces, workstations, and production areas — suitable for pharmaceutical, biotech, microbiology, and medical device applications.

Features:

• Non-woven polyester + cellulose blend for high absorbency

• Low-lint, low-particle design for cleanroom compatibility

• Soft, non-abrasive texture — safe for sensitive surfaces

• Good wet and dry strength for routine wiping tasks

• Suitable for spill control, surface cleaning and equipment wiping

• Available sizes: 9×9 and 12×12

• Economical and suitable for high-usage environments

• Ideal for ISO-classified cleanrooms, QA/QC, production & aseptic areas